Why advanced materials are critical to tomorrow’s cars and consumer goods

With demand rising for electric vehicles and autonomous driving technology, researchers are inventing new materials for everything from a vehicle’s exterior and interior to batteries and sensors to alternative powertrains. Such materials – including things like recyclable carbon fiber reinforced polymers to engineered molding compounds to new uses and chemistries for resin – are helping the auto industry and other startup mobility players make safer, more efficient and eco-friendly vehicles.

Déjà vu

Almost a half century ago, the oil crisis pushed the automobile industry to make drastic changes to their designs as consumers demanded cars with better fuel economy. The automakers needed components that weighed less and performed better than the metal parts that were used and so the widespread integration of polymers in the automotive industry began. Today, changes in how vehicles are designed, made, powered and used are catalyzing another transformation. In the face of this massive shift, specialty materials suppliers like Panasonic are collaborating with established industry players and vehicle startups to co-create the new mobility landscape.

And mobility is just one industry influencing demand for innovative, advanced materials. It’s no secret that consumer electronics are trending smaller. Consider the first satellite-based cellphone from the 1980’s, famous for its brick shape. Now, our smart phone doesn’t just fit in our pocket, but it also has more computing power than the most powerful desktops of an earlier era. It’s also a camera, a video editor, a music studio and more.

Creative uses of new materials in consumer goods

As electronics shrink, they are also being integrated into a surprising number of everyday items. Consider smart yoga pants that use haptic vibrations to encourage wearers to shift to better align or hold a pose during exercise. They are built with the wireless capacity to sync up to their user’s smart phone and provide further feedback. Advanced electronic materials are also a cornerstone of the Industrial Internet of Things revolution which is connecting millions of devices to help factories become more efficient.

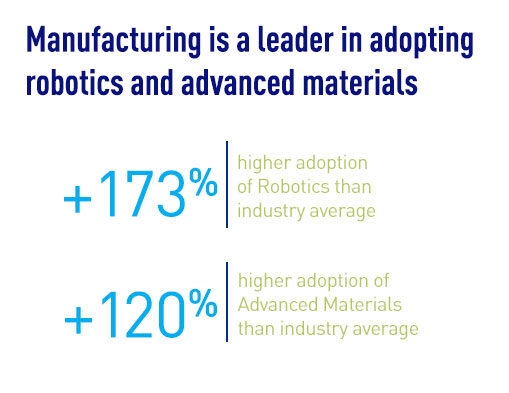

Much has been written about the leading 10 disruptive technologies that are expected to generate trillions of dollars in economic value in the decade ahead. We believe that shaping them into integrated solutions is the key to creating entirely new experiences. Recent research conducted by Panasonic on disruptive technologies shows that advanced materials are expected to be a near-term investment for two in five companies.

Advanced materials drawing investment

Even more interesting, some 38% of respondents in our disruptive tech in manufacturing study have already adopted advanced materials in their organizations – second only to cloud technology. The research showed that a majority of senior decision makers who responded clearly understand the risk in failing to adopt disruptive technologies. Nearly four in five companies believe industry competitors will pull ahead if they do not adopt or invest in such innovation.

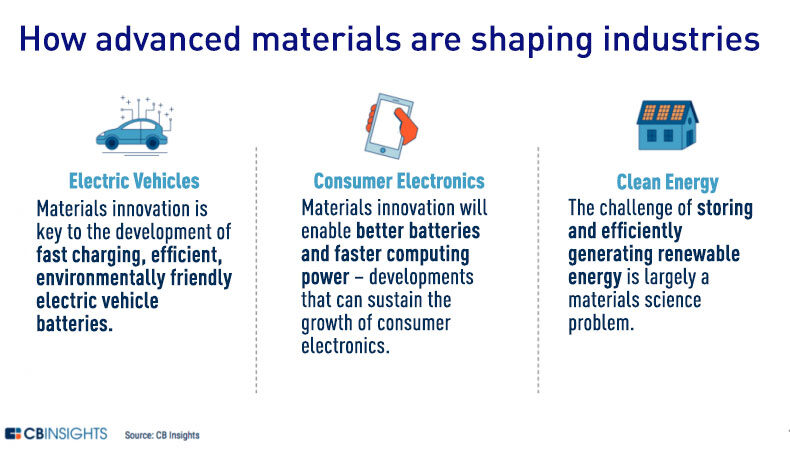

Already, the demand for advanced materials is impacting supply chains. High speed networks and new device form-factors are pushing innovators to pursue novel product designs and concepts. What industries are impacted? It’s hard to find one that isn’t. Advanced materials are playing a key role in developing fast charging, eco-friendly EV batteries, the next generation of mobile devices and untold consumer goods – to name a few.

Enabling new applications

These changes are driven by consumer demand for higher performance products and solutions and lower costs. Also powering the changes are fashion trends calling for smaller, thinner, more aesthetically pleasing devices and intuitive human-machine interfaces. Current generations of thermoplastic polyurethane and silicone rubber materials are bound to create challenges associated with adhesion, heat resistance and embrittlement for the design engineer using pliant circuits in emerging consumer products. And demand is rising among designers for conformable circuit materials that have excellent heat resistance, durability and workability.

Unique stretchable polymer technology

Combining the proven performance of conventional circuit fabrication and assembly processes with Panasonic's proprietary materials and design expertise, its innovators are creating novel materials that can be readily used to make stretchable circuits. The technology is based on a Panasonic proprietary resin system capable of stretching thousands of times and returning to its original length after every elongation cycle. Additionally, the base polymer is highly temperature resistant – surviving temperature excursions exceeding 260 degrees Celsius, which is hot enough to liquefy most electronic solders.

Circuits manufactured with these materials are super-pliable and adapt to desired manners of bending and folding. They may be applied to free-form surfaces, substantially reducing the design constraints experienced with conventional circuit boards. For example, the circuits can enable the construction of soft and stretchable electronic devices that are adaptable to a variety of forms such as wearable devices and automotive components. The material is deployable in a broad range of applications even beyond wearables and automotive including sensors, displays, medical, aerospace and soft-robotics. Look for the first of these new materials to be commercially available from Panasonic in the near future.

These stretchable circuit materials have been called a game changer – and they’re not the only ones in Panasonic’s portfolio. More than a century ago, an improved temperature resistant plastic light socket was the very first product manufactured by Panasonic. The socket was made from a then advanced material, a specialized resin and had a unique design. To learn more about Panasonic’s advanced materials research – and how they enable stretchable hybrid electronics – contact our sales team.